The Fashion Industry’s Waste Crisis

Zero waste fashion is revolutionizing the industry, addressing the problem of unsold clothing waste through technology like 3D printing and on-demand manufacturing. These garments are often discarded in landfills or incinerated, releasing toxic pollutants into the environment.

To address this crisis, the industry must rethink how to produce more with fewer resources.

Additionally, while some designers explore alternative textiles, others are turning to zero-waste technology, including 3D printing, spray-on fabrics, and digital manufacturing.

Zero Waste Fashion and 3D Printing: A Revolution in Sustainable Design

One of the pioneers of zero-waste fashion technology is Iris Van Herpen, a designer known for pushing the boundaries of haute couture.

Her latest innovation, the “Infinity” dress, was created in collaboration with kinetic sculptor Anthony Howe.

How 3D Printing Reduces Waste:

- Precision Production: No excess fabric or scraps.

- Sustainable Materials: Some designers use biodegradable or recycled filaments.

- Customization & Efficiency: made on-demand, reducing inventory waste.

The 3D printing is changing the way fashion is designed and produced and offers a sustainable alternative to traditional garment-making.

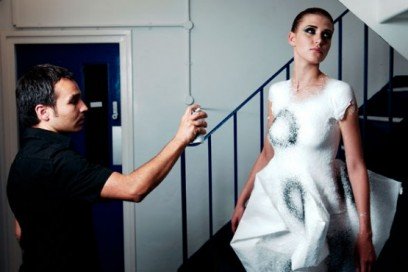

Spray-On Fabric: The Future of Instant Clothing

Fabrican, a British company, has developed a spray-on fabric that could revolutionize sustainable fashion.

How Fabrican Works:

- Liquefied fibers are sprayed onto a body or dress form.

- The solvent evaporates, and the fibers bond together, forming a perfectly fitted garment.

- No sewing, cutting, or fabric waste is involved.

On-Demand Manufacturing: Reducing Excess Production

Unmade, a software company, tackles fashion’s waste problem with customized, on-demand production.

How Unmade’s Technology Works:

- Consumers customize garments online, selecting colors, styles, and patterns.

- The brand produces the item only after a live transaction, ensuring there is no overproduction.

By using real-time data and digital production, Unmade is helping brands shift from mass production to a more responsible, waste-free approach.

Waterless Dyeing: Sustainable Textile Printing

Intech Digital is revolutionizing textile dyeing with its waterless printing technology, offering an eco-friendly alternative to traditional dyeing processes.

The Benefits of Waterless Printing:

- Eliminates water usage in textile dyeing.

- Uses digital programs for precise color application.

- Reduces environmental impact and toxic waste.

In a world where fashion sustainability is no longer optional, technologies like Intech Digital’s printing process demonstrate that the industry is moving towards a greener, waste-free future.

The Future of Fashion: Innovation & Sustainability

From 3D printing and spray-on fabrics to on-demand production and waterless dyeing, technology is transforming fashion into a more sustainable industry.

By embracing zero-waste solutions, brands can reduce environmental impact and continuing to innovate.

Is the future of fashion completely waste-free? Only time will tell, and one thing is certain: technology is leading the way toward a more responsible industry.